Our Products

Shanghai Turbo specialises in the production of precision vane products, which are the key components of steam turbine power generators. Our vane products are mainly sold to manufacturers of steam turbine power generators, either for the production of new units or as replacement and upgrading parts for existing ones.

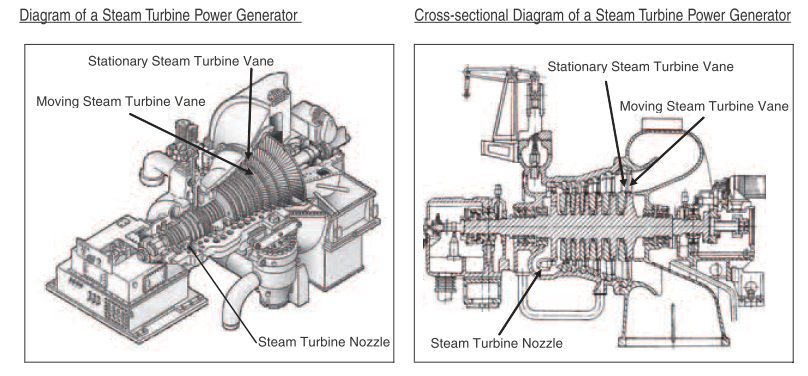

A steam turbine power generator converts kinetic energy from pressurised superheated steam into electrical energy. A typical generator consists of a steel shell, in which a series of bladed disks are systematically aligned along a central shaft. Each bladed disk is made up of moving steam turbine vanes which curve and radiate outwards, and in-between each pair of bladed disks is a row of stationary steam turbine vanes which extend radially inward. As high pressure steam enters the generator, it strikes the stationary steam turbine vanes, which direct the steam against the first bladed disk at an optimum speed and angle. The steam then passes through the adjacent bladed disk, turning the moving steam turbine vanes. Most steam turbines have multiple sets of blades, or stages, and as the steam moves through the stages, this moves the blades and the central shaft, which is attached to an electrical generator.

Shanghai Turbo manufactures steam turbine stationary vanes, steam turbine moving vanes, as well as the steam turbine nozzles which apply pressurised superheated steam to the vanes at high speed. In general, depending on the generating capacity of the steam turbine power generator, a complete set of steam turbine vanes will consist of up to 8,000 vane products – a combination of stationary, moving vanes and nozzles of various lengths as well as different types of nozzles. The average usable life of a vane is between 5-10 years.

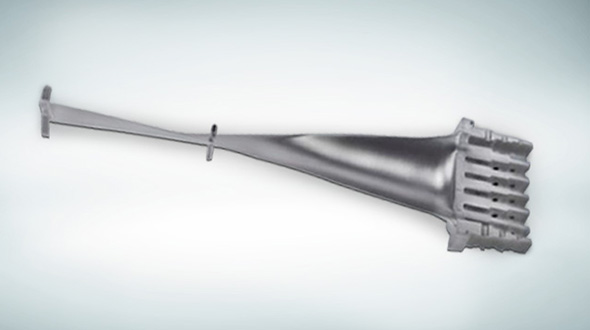

Moving Vanes

In a steam turbine power generator, moving vanes are joined together to form a circle, and spun by pressurised superheated steam. The level of precision of moving vanes is critical to the stability and performance of a steam turbine power generator, as the joint moving vanes rotate at high velocity under high pressure and high temperature conditions. Any crack or excessive space between the joined vanes will give rise to erosion due to high-speed particles and moisture, which reduces the physical life of the vanes and the efficiency of the steam turbine.

We are capable of producing a complete set of steam turbine moving vanes of up to 1068 mm in length, which are used for steam turbine power generators each with a generating capacity of up to 600,000 KW of electricity. For single pieces of vanes, we are capable of producing for steam turbine power generators with a generating capacity of up to 1,000,000 KW of electricity

ROOT VANE

(纵树型叶根)

TURBINE VANE

(涡轮动叶片)

LAST STAGE MOVING VANE

(末极动叶片)

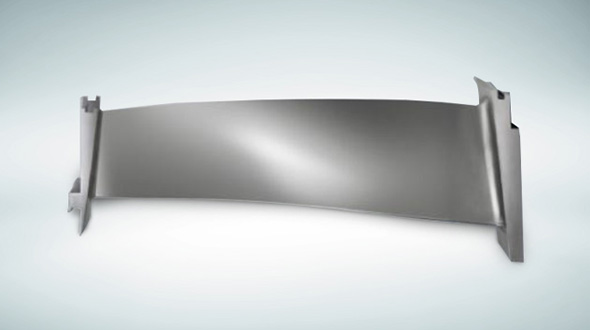

Stationary Vanes

Steam turbine stationary vanes are mounted on the casing of a steam turbine power generator and serve to redirect the steam towards the adjacent moving vanes. They are designed and manufactured to high levels of precision in order to maximise the efficiency of the flow of steam.

We are capable of producing a complete set of steam turbine stationary vanes of up to 1,000 mm in length, which are used for steam turbine power generators each with a generating capacity of up to 600,000 KW of electricity. For single pieces of vanes, we are capable of producing for steam turbine power generators with a generating capacity of up to 1,000,000 KW of electricity.

COMPRESSOR STATOR VANE

(压气机静叶片)

STATIONARY VANE

(静叶片)

COMPANY

INFORMATION

BUSINESS

SOLUTIONS